Quality Commitment

We, YUANTAIDERUN, are fully committed to customer satisfaction. As a guarantee of project safety, we have established our quality policy and are committed to creating a safer world by providing better, innovative and effective products and services. It's a never-ending process - we continually review our quality systems and products against regulatory requirements to ensure we're on the right path.

We share our customers' concerns and understand that they need proper consultation and proper after sales when they need it, which is why we always strive to do better and more on this important issue.

The quality policy below reflects our company's focus on providing steel pipe products that our customers can trust. We have worked hard to build and maintain this trust over the years

- Delight our customers and deliver Better Quality promise.

- Design and deliver safe, excellent cost, and effective products.

- Comply with applicable regulatory & compliance requirements and enhance everyone’s duty for quality.

- Drive a culture of continuous improvement.

Project kick off meeting

Heads of various departments of yuantaiderun

Yuantaiderun has 20 years of steel pipe manufacturing experience and project follow-up management experience

Certificates

YUANTAIDERUN has been Certified by ECI according to ISO9001:2015 and ISO14001:2015. Also we are qualified CNAS sterilization service provider (holder of ISO45001:2015 certificate).

In Europe, we have aquired the EN10210/EN10219 certification.

Certificate: BC1/BV/PHD/EPD/CE/ISO/JIS

- ISO9001: 2015

- EN10219/EN10210

- JIS G3466

- EPD

- PHD

- BC1

We have a well qualified team….

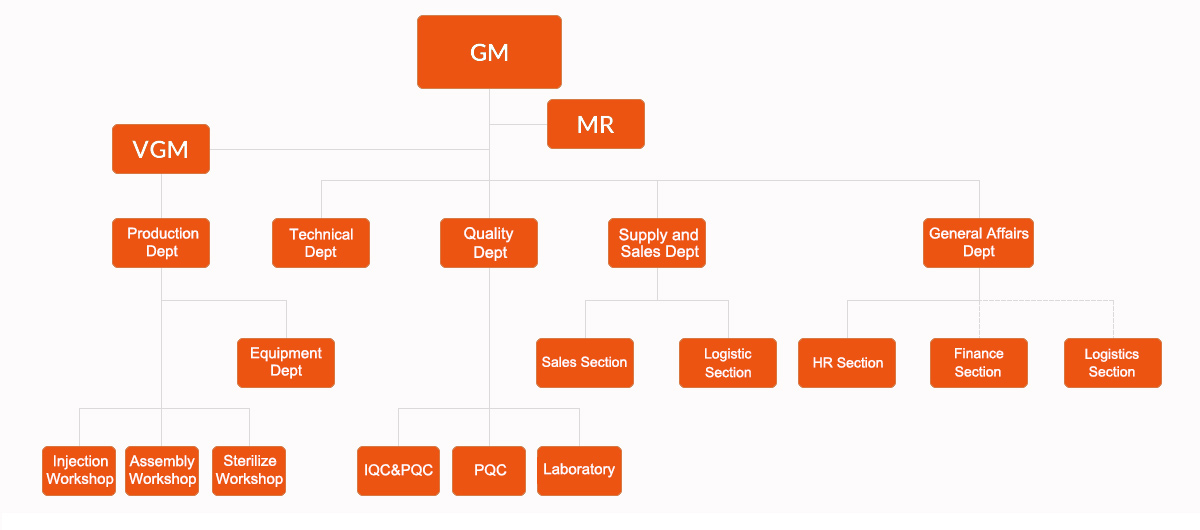

The whole organization takes quality as our first priority.

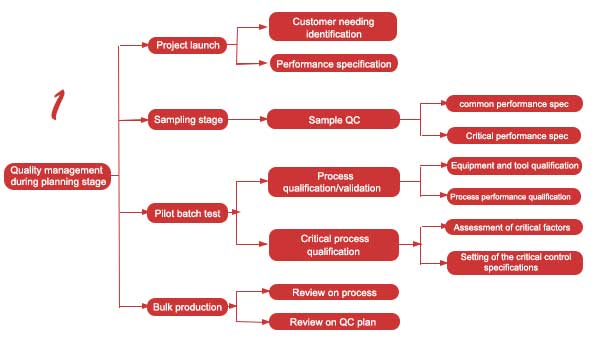

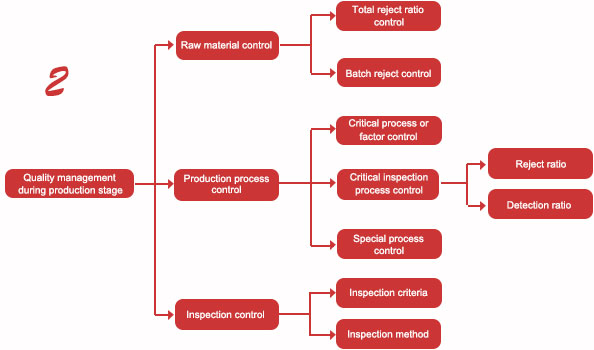

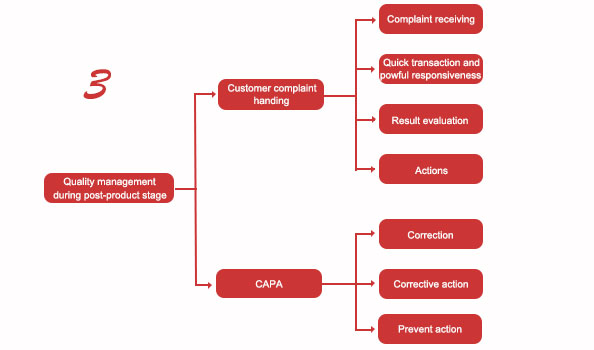

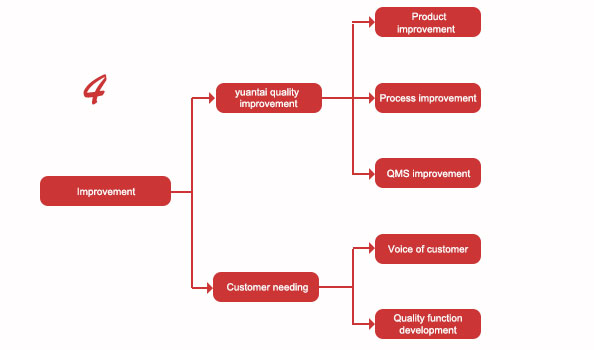

- Total Quality Management

Planning

Production

Post-product

Improvement

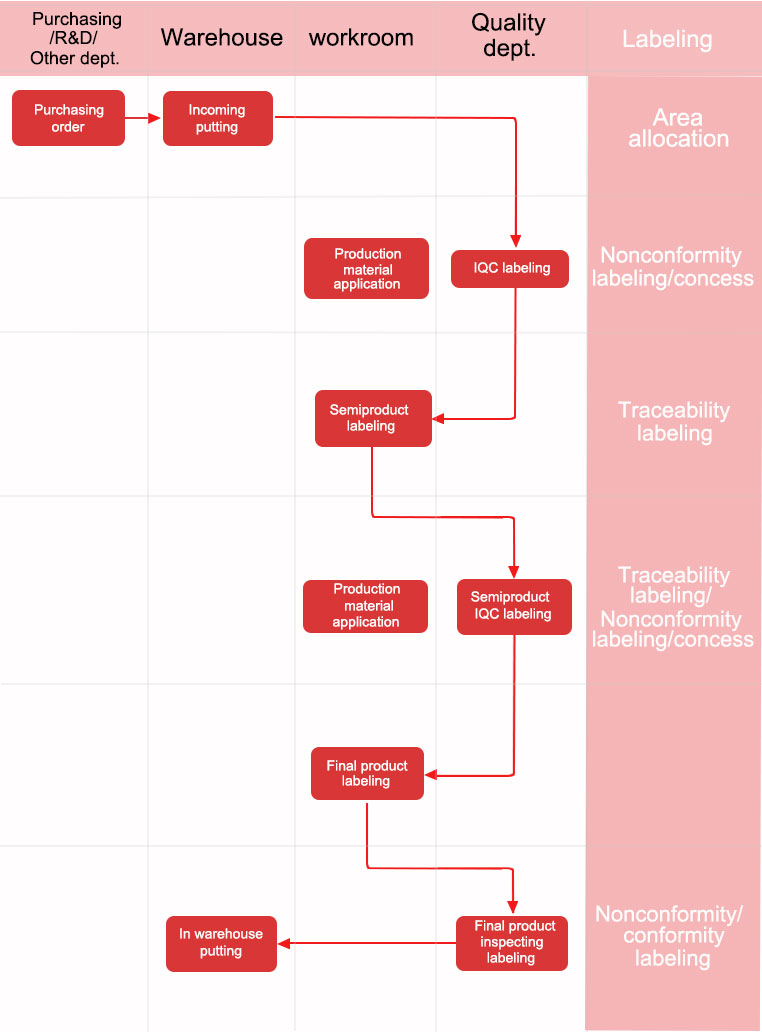

Traceability is one of the most important aspects of steel pipe products and our QMS system, not only in the product realization stage, but also in the whole project life cycle. In order to protect customers and avoid the illegal abuse of steel pipe building materials, we care about and attach great importance to the traceability of products. The handling of post marketing supervision of steel pipes is an important issue in our quality management system. Traceability ensures that we implement the PMS system in the way originally designed. Through this system, the risks can be minimized and the interests of customers can be maximized.

In the product realization stage, DHR is the core part of the whole traceability system. DHR includes each process record, such as raw material inspection record, manufacturing record according to the planned schedule, process inspection and galvanizing batch record, which can be provided on request.

Each senior customer consultant tracks the product throughout the product life cycle.

Traceability during product realization stage:

- Tel:

86-22-58951962

- Email:

- sales@ytdrgg.com

- WhatsApp:

- https://wa.me/8613682051821

- Address:

- No. 1, Hengtong Road, Daqiuzhuang Town, Jinghai District, Tianjin

- Email:

- sales@ytdrgg.com

- square&rectangular steel tube

- ERW steel pipe

- Ship Building Steel Pipe

- LSAW steel pipe

- seamless steel pipe

- galvanized steel pipe

- spiral steel pipe

- special shaped steel pipe

- line pipe&OCTG pipe

- stainless steel tube/coil

- Steel coil / steel strip / steel plate / angle steel / channel steel / H-section steel/steel spiral ground pile